Nkhaniyi ifotokoza malingaliro apangidwe ndi kukonza ndondomeko ya chivundikiro cha bokosi la nkhomaliro mwatsatanetsatane, ndi mapangidwe a pulasitiki, zipangizo zowunikira mwatsatanetsatane, kapangidwe kake ka teknoloji ya nkhungu.

Mawu ofunika: jekeseni nkhungu;Phukusi lankhomaliro.Kuumba ndondomeko

Gawo Loyamba:Kusanthula kwa magawo apulasitiki ndi kusankha koyambirira kwa makina ojambulira

1.1Zopangira ndi kusanthula magwiridwe antchito a bokosi la nkhomaliro la pulasitiki

Bokosi la nkhomaliro la pulasitiki ili ndi chinthu chodziwika bwino cha pulasitiki m'moyo watsiku ndi tsiku, chomwe chimagwiritsidwa ntchito kusungira chakudya.Poganizira za kugwiritsidwa ntchito kwake, kusanthula kwathunthu kwa magwiridwe antchito a mapulasitiki osiyanasiyana, kusankha kwazinthu za polypropylene (PP).

Polypropylene (PP pulasitiki) ndi mtundu wa kachulukidwe mkulu, palibe unyolo mbali, mkulu crystallization wa liniya polima, ali kwambiri mabuku katundu.Pamene siakuda, woyera translucent, waxy;Opepuka kuposa polyethylene.Transparency ndi bwino kuposa polyethylene.Kuonjezera apo, kachulukidwe ka polypropylene ndi kakang'ono, mphamvu yokoka yeniyeni ya 0.9 ~ 0.91 magalamu / kiyubiki centimita, mphamvu zokolola, elasticity, kuuma ndi kugwedezeka, mphamvu yopondereza ndipamwamba kuposa polyethylene.Kutentha kwake ndi 160 ~ 220 ℃, kungagwiritsidwe ntchito pafupifupi madigiri 100, ndipo kumakhala ndi magetsi abwino komanso kutsekemera kwafupipafupi sikukhudzidwa ndi chinyezi.Mayamwidwe ake amadzi ndi otsika kuposa polyethylene, koma mosavuta kusungunula kupasuka kwa thupi, kukhudzana kwanthawi yayitali ndi chitsulo chotentha ndikosavuta kuwola, kukalamba.The fluidity ndi zabwino, koma kupanga shrinkage mlingo ndi 1.0 ~ 2.5%, shrinkage mlingo waukulu, amene n'zosavuta kutsogolera shrinkage dzenje, dent, kupunduka ndi zolakwika zina.Polypropylene kuzirala liwiro ndi kudya, kuthira dongosolo ndi kuzirala dongosolo ayenera pang'onopang'ono kuzirala, ndi kulabadira kulamulira kupanga kutentha.Makulidwe a khoma la zigawo za pulasitiki ayenera kukhala yunifolomu kupewa kusowa guluu ndi lakuthwa ngodya kupewa nkhawa ndende.

1.2Kusanthula kwa njira yopangira nkhomaliro ya pulasitiki

1.2.1.Kusanthula kwamapangidwe a zigawo zapulasitiki

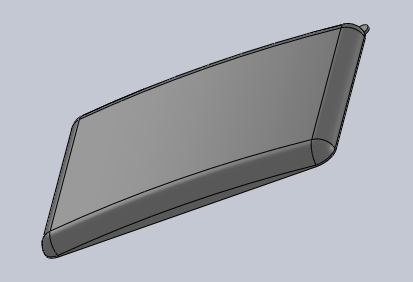

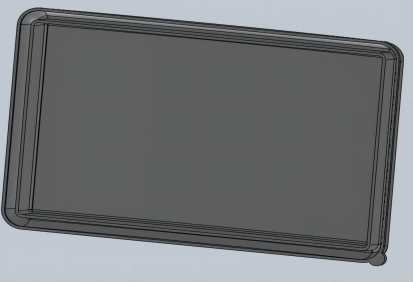

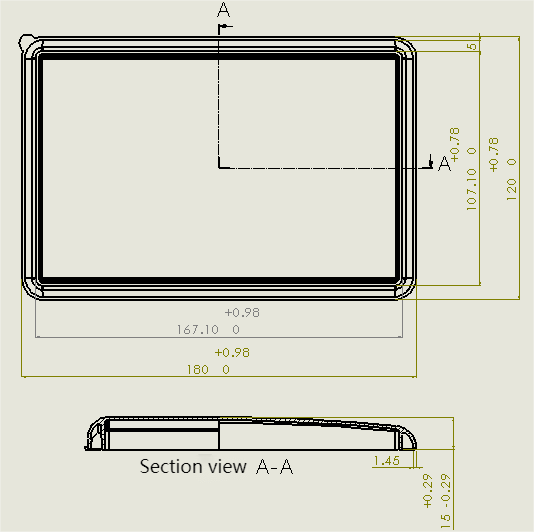

The analimbikitsa khoma makulidwe a polypropylene tinthu tating'ono pulasitiki ndi 1.45mm;Kukula koyambirira kwa bokosi la nkhomaliro ndi 180mm×120mm×15mm;Tengani kukula kwa khoma lamkati la chivundikiro cha bokosi la masana: 107mm;Kusiyana kwa makoma amkati ndi akunja ndi: 5mm;Ngodya yozungulira ya khoma lakunja ndi 10mm, ndipo ngodya yozungulira ya khoma lamkati ndi 10/3mm.Ngodya imodzi ya chivundikiro cha bokosi ili ndi bwana wa annular wokhala ndi utali wa 4mm.Chifukwa mbali za pulasitiki ndi zitsulo zokhala ndi mipanda yopyapyala, pofuna kupewa kusowa kwa kuuma ndi mphamvu zomwe zimayambitsidwa ndi mapulasitiki a pulasitiki, kotero pamwamba pa zigawo za pulasitiki zimapangidwa ngati bwalo la 5mm mkulu wa arc.

1.2.2.Dimensional mwatsatanetsatane kusanthula mbali pulasitiki

Miyeso iwiri ya chivundikiro cha bokosi la nkhomaliro ili ndi zofunikira zolondola, zomwe ndi 107mm ndi 120mm, ndipo zofunikira zolondola ndi MT3.Popeza mbali yakunja ya zigawo za pulasitiki imakhudzidwa ndi kulekerera kwa miyeso ya gawo losunthika la nkhungu (monga m'mphepete mwa ndege), mtundu wolekerera umasankhidwa ngati kalasi B. Ngati kulekerera sikufunikira, MT5 imasankhidwa. .

1.2.3.Kusanthula kwapamwamba kwa zigawo zapulasitiki

Kulondola kwapamwamba kwa chivundikiro cha bokosi la nkhomaliro sikwapamwamba, ndipo pamwamba pa roughness Ra ndi 0.100 ~ 0.16um.Chifukwa chake, jekeseni imodzi yokhayokha pamwamba pa jekeseni wothamanga pa chipata angagwiritsidwe ntchito kuti atsimikizire kulondola kwapamwamba.

1.2.4.Zinthu zakuthupi ndi voliyumu ndi mtundu wa magawo apulasitiki

Funsani zinthu zakuthupi za pulasitiki ya PP (kuphatikiza zotanuka modulus, chiŵerengero cha Poisson, kachulukidwe, mphamvu zomangika, matenthedwe otentha ndi kutentha kwapadera) mu SolidWorks, ndikugwiritsa ntchito pulogalamu ya SolidWorks kuwerengera deta ya zigawo zapulasitiki (kuphatikiza kulemera, voliyumu, pamwamba ndi pakati. wa mphamvu yokoka).

1.3 Kudziwa akamaumba magawo magawo pulasitiki

Popanga jekeseni, kutentha kwa silinda ndi nozzle kumakhudza pulasitiki ndi kutuluka kwa pulasitiki, kutentha kwa nkhungu kumakhudza kutuluka ndi kuzizira kwa mawonekedwe a pulasitiki, kupanikizika pakupanga jekeseni kumakhudza mwachindunji plasticization wa pulasitiki ndi pulasitiki mbali khalidwe.Kupanga pankhani ya kuonetsetsa kuti mbali za pulasitiki zili bwino, ndiyesa kufupikitsa kuzungulira kwa zigawo zapulasitiki, zomwe nthawi ya jekeseni ndi nthawi yozizirira zimakhudza kwambiri mawonekedwe a pulasitiki.

Mafunso oyenera kuganizira popanga:

1) Kugwiritsa ntchito moyenera ma stabilizers, mafuta opangira mafuta kuti awonetsetse kuti pulasitiki ya PP ikugwira ntchito komanso kugwiritsa ntchito zida zapulasitiki.

2) Shrinkage, indentation, deformation ndi zolakwika zina ziyenera kupewedwa panthawi yopanga.

3) Chifukwa cha kuthamanga kwachangu kuzizira, tcherani khutu kutentha kwa kutentha kwa dongosolo lothira ndi dongosolo lozizira, ndipo samalani ndi kuwongolera kutentha kwa kupanga.Pamene kutentha kwa nkhungu kumakhala kochepa kuposa madigiri a 50, mbali za pulasitiki sizidzakhala zosalala, padzakhala kuwotcherera bwino, kusiya zizindikiro ndi zochitika zina;Madigiri opitilira 90 amatha kusinthika kwa warp ndi zochitika zina.

4) Makulidwe a khoma la magawo apulasitiki azikhala ofanana kuti apewe kupsinjika.

1.4 Chitsanzo ndi ndondomeko ya makina opangira jekeseni

Malinga ndi akamaumba magawo magawo pulasitiki, kusankha koyamba kwa m'nyumba G54-S200/400 chitsanzo jekeseni makina akamaumba,

Gawo Lachiwiri: Mapangidwe apangidwe a pulasitiki nkhomaliro bokosi chivundikiro jekeseni nkhungu

2.1 Kutsimikiza kwa malo olekanitsa

Mawonekedwe oyambira ndi kufooketsa magawo apulasitiki ayenera kuganiziridwa posankha malo olekanitsa.Mfundo za kapangidwe ka malo olekanitsa ndi awa:

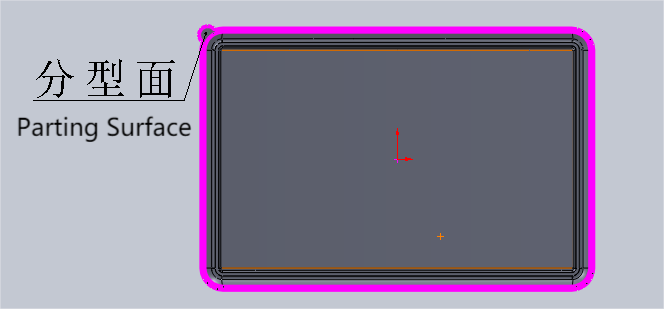

1. Gawo logawanika liyenera kusankhidwa pamtunda waukulu wa gawo la pulasitiki

2. Kusankhidwa kwa malo olekanitsa kuyenera kukhala kothandiza kuti mapulasitiki apangidwe bwino

3. Kusankhidwa kwa malo olekanitsa kuyenera kuwonetsetsa kulondola kwapang'onopang'ono komanso mawonekedwe apamwamba a zigawo zapulasitiki ndi zomwe amafunikira kugwiritsa ntchito.

4. Kusankhidwa kwa malo olekanitsa kuyenera kukhala kothandiza pakukonza ndi kuphweka kwa nkhungu

5. Chepetsani malo owonetsera mankhwalawo kuti agwirizane ndi clamping

6. Pakatikati patali iyenera kuyikidwa kumbali yotsegulira kufa

7. Kusankha malo olekanitsa kuyenera kukhala kothandiza kutulutsa mpweya

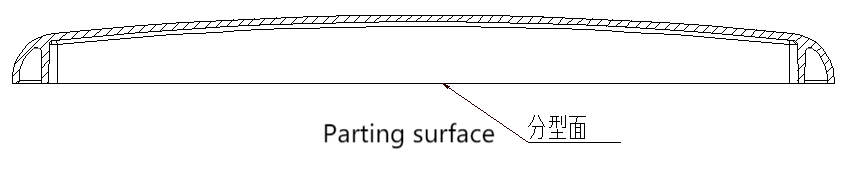

Mwachidule, pofuna kuonetsetsa yosalala demoulding wa mbali pulasitiki ndi zofunika luso mbali pulasitiki ndi kupanga yosavuta nkhungu, polekanitsa pamwamba amasankhidwa monga m'munsi pamwamba pa nkhomaliro bokosi chivundikirocho.Monga momwe chithunzi chili pansipa:

2.2 Kutsimikiza kwa nambala ya Cavity ndi kasinthidwe

Malinga ndi zofunikira za kapangidwe ka magawo apulasitiki, mawonekedwe amtundu wa geometric mawonekedwe ndi zofunikira pazachuma komanso zofunikira pazachuma pakupanga, dziwani kugwiritsa ntchito nkhungu pabowo.

2.3 Mapangidwe a dongosolo lothira

Kapangidwe kameneka kamagwiritsa ntchito njira yothira wamba, ndipo mfundo zake ndi izi:

Sungani njira yayifupi.

Kutentha kuyenera kukhala bwino,

Kuletsa deformation yoyambira ndikuyika kusamuka,

Kupewa warping mapindikidwe mbali pulasitiki ndi mapangidwe ozizira zipsera, mawanga ozizira ndi zina zolakwika padziko.

2.3.1 Mapangidwe apamwamba a njira

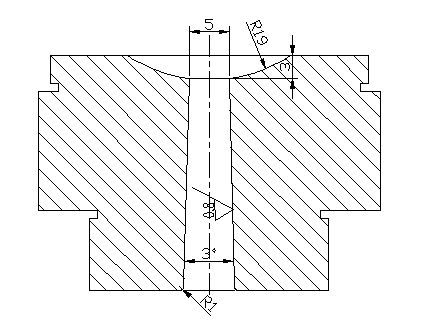

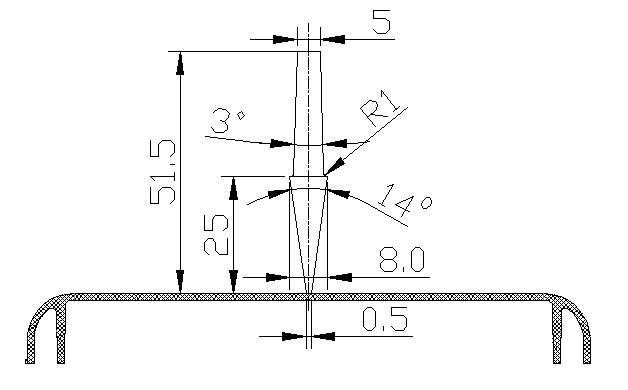

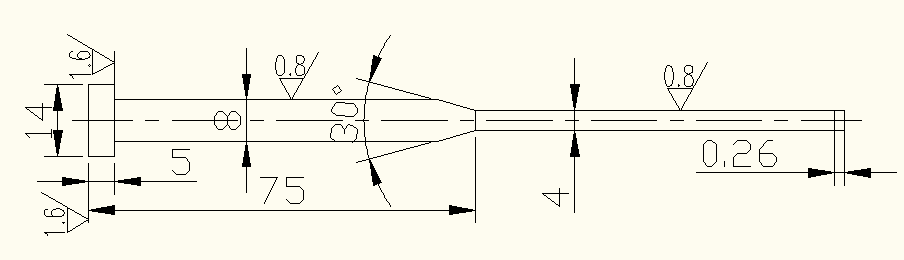

Njira yayikulu idapangidwa kuti ikhale yowoneka bwino, ndipo cone Angle α ndi 2O-6O, ndi α = 3o.Kukula kwamphamvu kwa njira yotuluka Ra≤0.8µm, kutuluka kwa njira yayikulu ndikusintha kwa fillet, kuti muchepetse kukana kwa zinthu zomwe zikuyenda pakusintha, fillet radius r = 1 ~ 3mm, imatengedwa ngati 1mm. .Kamangidwe kameneka kameneka kali motere;

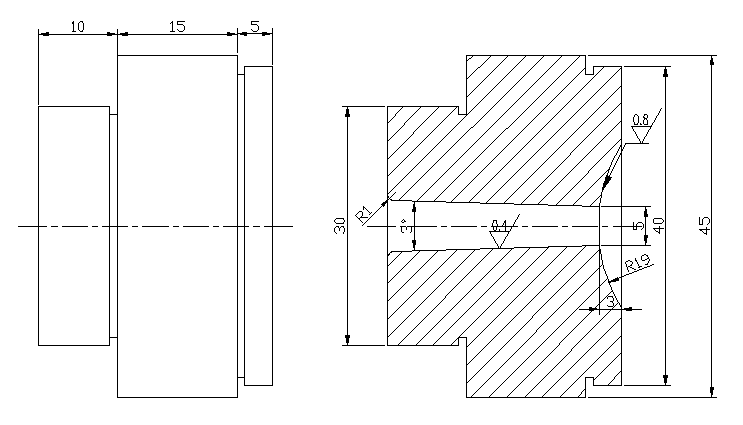

Mapangidwe a manja a pachipata amapangidwa kukhala magawo awiri pogwiritsa ntchito chikhomo cha chipata ndi mphete yoyikapo, yomwe imayikidwa pa mbale yokhazikika ya kufa ngati sitepe.

M'mimba mwake kumapeto kwakung'ono kwa manja a pachipata ndi 0.5 ~ 1mm yayikulu kuposa ya nozzle, yomwe imatengedwa ngati 1mm.Popeza kutsogolo kwa mapeto ang'onoang'ono ndi gawo, kuya kwake ndi 3 ~ 5mm, komwe kumatengedwa ngati 3mm.Popeza gawo la nozzle ya makina a jakisoni amalumikizana ndikukwanira nkhungu pamalopo, kutalika kwa gawo la njira yayikulu kumafunika kukhala 1 ~ 2mm yayikulu kuposa ya nozzle, yomwe imatengedwa ngati 2mm.Mawonekedwe ogwiritsira ntchito ndi magawo a mkono wa pachipata akuwonetsedwa pansipa:

H7/m6 kusintha kokwanira kumatengedwa pakati pa dzanja lachipata ndi template, ndipo kukwanira kwa H9/f9 kumatengedwa pakati pa mkono wa pachipata ndi mphete yoyika.Mphete yoyikapo imayikidwa mu dzenje loyikamo template yokhazikika ya makina ojambulira panthawi yoyika ndikuwongolera nkhungu, yomwe imagwiritsidwa ntchito pakuyika ndikuyika nkhungu ndi makina ojambulira.M'mimba mwake wakunja kwa mphete yoyikapo ndi 0.2mm yaying'ono kuposa dzenje loyika pa template yokhazikika ya makina ojambulira, kotero ndi 0.2mm.Mawonekedwe okhazikika a manja a pachipata ndi kukula kwa mphete yoyika zikuwonetsedwa pansipa:

2.3.2 Shunt kanjira

Chifukwa kapangidwe ndi nkhungu patsekeke, kugawanika pamwamba pansi pa bokosi chivundikirocho, ndi kusankha pachipata kwa mfundo pachipata mtundu mwachindunji, kotero shunt alibe kupanga.

2.3.3 Kapangidwe ka zipata

Poganizira zofunika akamaumba mbali pulasitiki ndi nkhungu processing ndi yabwino kapena ayi ndi ntchito yeniyeni ya zinthu, kotero kamangidwe ka pachipata malo amasankhidwa pamwamba pakati pa nkhomaliro bokosi chivundikirocho.Kutalika kwa chipata cha mfundo nthawi zambiri kumakhala 0.5 ~ 1.5mm, ndipo kumatengedwa ngati 0.5mm.Angle α nthawi zambiri imakhala 6o ~ 15o, ndipo imatengedwa ngati 14o.Mapangidwe a chipata akuwonetsedwa pansipa:

2.4 Mapangidwe a dzenje lozizira ndi ndodo yokoka

Choncho, kapangidwe ndi nkhungu ndi patsekeke, mfundo chipata mwachindunji kuthira, kotero ozizira dzenje ndi kukoka ndodo sayenera kupangidwa.

2.5 Mapangidwe opanga magawo

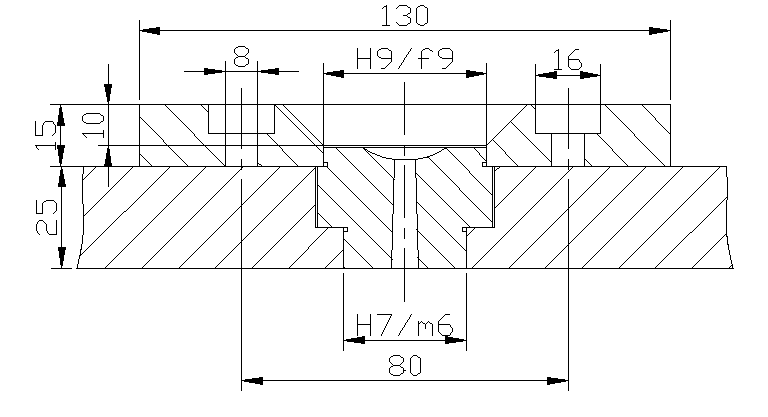

2.5.1Kutsimikiza kwa kufa ndi nkhonya kapangidwe

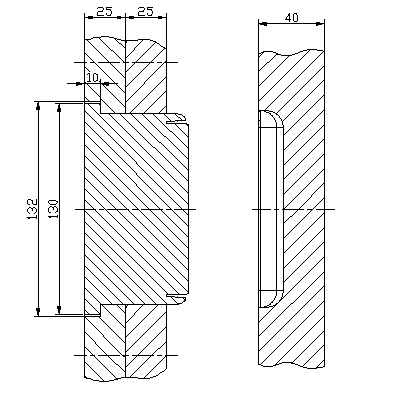

Chifukwa ndi mbali yaing'ono pulasitiki, patsekeke, ndi kuti mkulu processing Mwachangu, yabwino disassembly, komanso kuonetsetsa mawonekedwe ndi kukula zolondola mbali pulasitiki, kamangidwe ka otukukira pansi wonse ndi concave kufa kusankha lonse.The convex kufa ndi kukonzedwa ndi osiyana processing njira, ndiyeno mbamuikha mu Chinsinsi ndi H7/m6 kusintha.Chithunzi chojambula cha mapangidwe a convex ndi concave die ndi motere:

2.5.2Kupanga ndi kuwerengera kwa patsekeke ndi kapangidwe kapakati

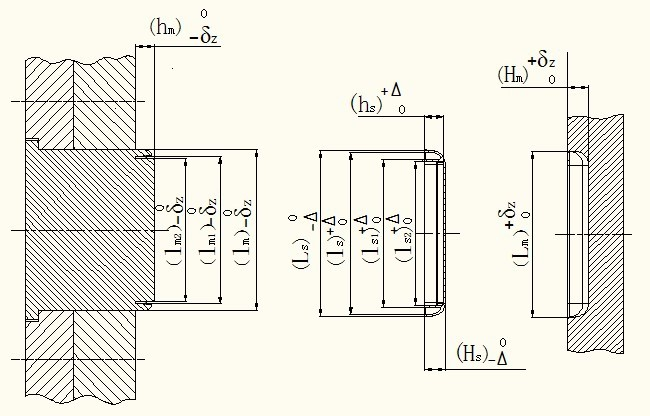

Ubale pakati pa kukula kwa ntchito ya gawo la nkhungu ndi kukula kwa gawo la pulasitiki zikuwonetsedwa pansipa:

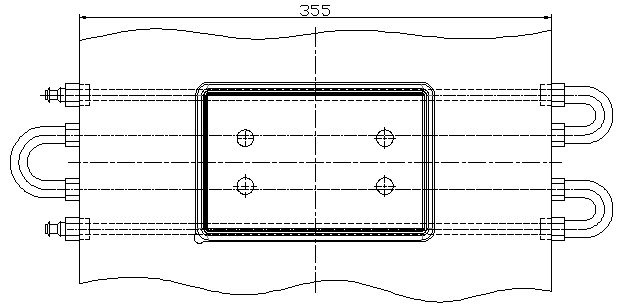

2.6 Kusankhidwa kwa chimango cha nkhungu

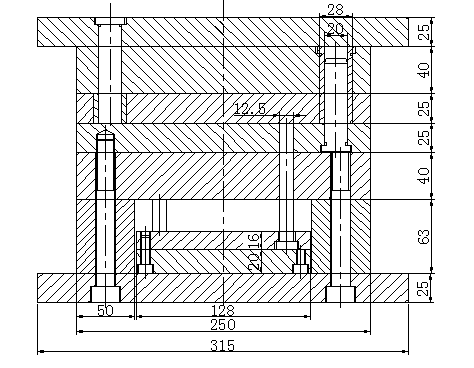

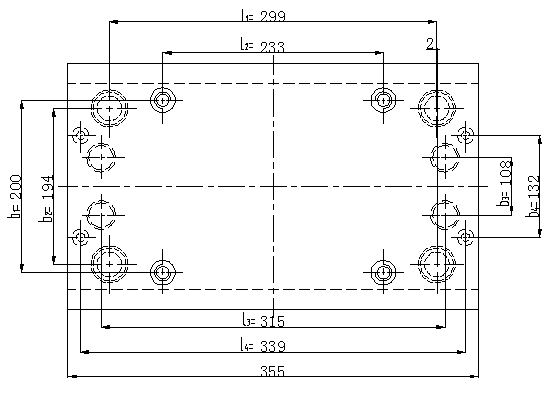

Popeza kapangidwe kameneka ndi kagawo kakang'ono komanso kakulidwe ka pulasitiki, chimango cha nkhungu ndi P4-250355-26-Z1 GB/T12556.1-90, ndipo B0 × L ya chimango cha nkhungu ndi 250mm×355mm.

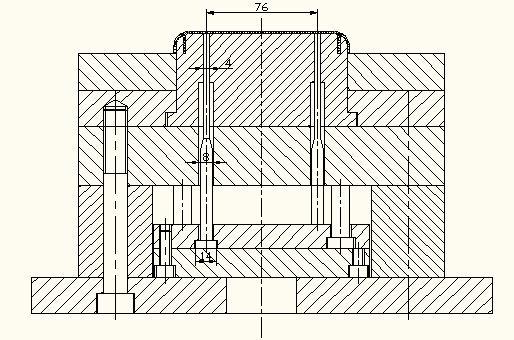

Chiwonetsero cha msonkhano wa mold chili motere:

2.7 Mapangidwe azinthu zomanga

2.7.1Kapangidwe kagawo kakuwongolera

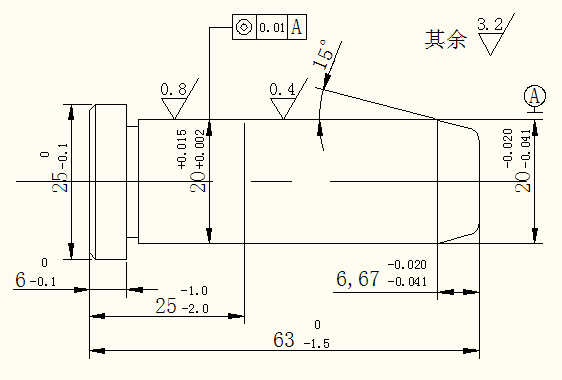

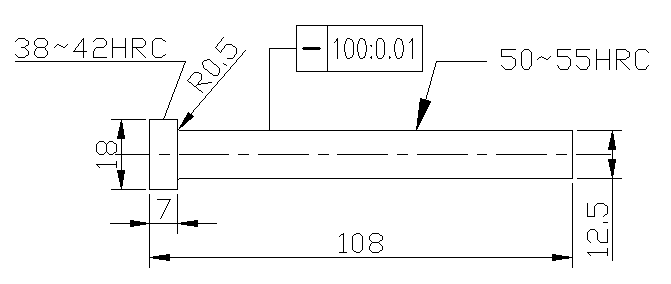

Kuzama kwa positi yolondolera ndi Φ20, ndipo zinthu zomwe zasankhidwa positi yolondolera ndi zitsulo 20, zokhala ndi carburizing 0.5 ~ 0.8mm ndikuzimitsa kuuma kwa 56 ~ 60HRC.Angle chamfered akuwonetsedwa pachithunzichi sichoposa 0.5 × 450.Chotsatira chowongolera chalembedwa kuti Φ20 × 63 × 25 (I) — 20 zitsulo GB4169.4 — 84. H7 / m6 kusintha koyenera kumatengedwa pakati pa gawo lokhazikika la ndondomeko ya ndondomeko ndi template.Chotsatira china chowongolera chalembedwa Φ20×112×32 — 20 zitsulo GB4169.4 — 84.

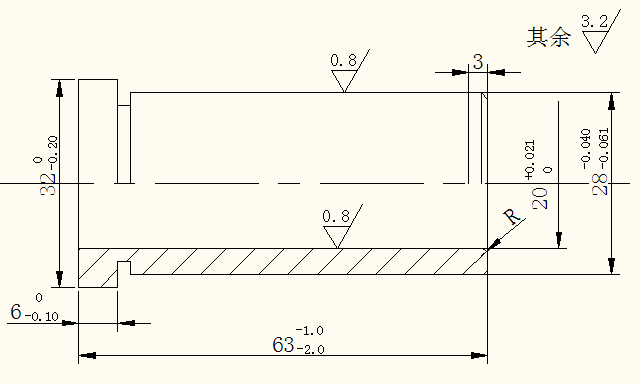

2.7.2Kuwongolera kapangidwe ka manja

M'mimba mwake wa manja owongolera ndi Φ28, ndipo zida za chitsulo chowongolera ndi zitsulo 20, carburized 0.5 ~ 0.8mm, ndipo kuuma kwa chithandizo chozimitsidwa ndi 56 ~ 60HRC.Kuwoneka kwachithunzichi sikuposa 0.5 × 450.Nkhola yolondolerayo ili ndi chizindikiro Φ20×63(I) — 20 zitsulo GB4169.3 — 84, ndipo kulondola kofananira kwa positi yolondolera ndi manja owongolera ndi H7/f7.Nkhola ina yolondolera yolembedwa Φ20×50(I) — 20 zitsulo GB4169.3 — 84.

2.8 Yambitsani makina opangira

Njira yokankhira nthawi zambiri imakhala ndi kukankha, kukonzanso ndi kuwongolera.

Chifukwa zigawo za pulasitiki ndizochepa thupi, poyesa kuwonetsetsa mawonekedwe a pulasitiki, mapangidwe a makina otsegulira amatengera ndodo ya ejector kukankhira mbali zapulasitiki.

Chithunzi chojambula cha makina oyambitsandi motere:

Kapangidwe ndi magawo a kukankha ndodoakuwonetsedwa pansipa:

The structural mawonekedwe ndi magawo a bwererani ndodoakuwonetsedwa pansipa:

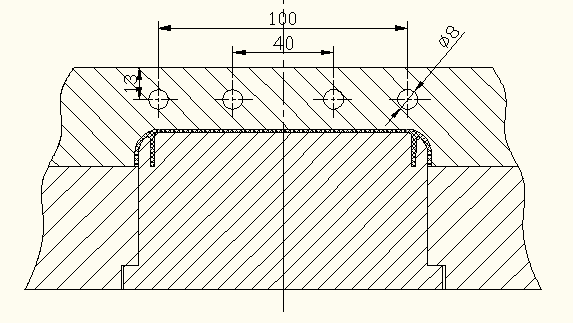

2.9 Mapangidwe a makina ozizira

Monga kuzizira sikuli yunifolomu, dongosolo lozizira la njira yozizira liyenera kukhala momwe lingathere, chisankho chokonzekera ichi cha 4. Mtunda wa njira kuchokera pamtunda ndi wofanana, ndipo sprue imalimbikitsidwanso kuti ikhale yozizira.Dongosolo lozizira limatengera mtundu wozungulira wa DC, womwe umakhala ndi mawonekedwe osavuta komanso osavuta kukonza.

Mapangidwe a cooling system ali motere:

Gawo Lachitatu: Onani mawerengedwe a nkhungu ya jakisoni

3.1.Check zokhudzana ndondomeko magawo a jekeseni makina

3.1.1 Onani kuchuluka kwa jekeseni

3.1.2 Yang'anani mphamvu ya clamping

3.1.3 Onani ulendo wotsegulira nkhungu

3.2.Yang'anani makulidwe a khoma lakumbali ndi mbale yapansi ya rectangular cavity

3.2.1 Yang'anani makulidwe a khoma lam'mbali lapakatikati

3.2.2 Yang'anani makulidwe a mbale yapansi ya rectangular

mapeto

Wopanga timu ya Freshness Keeper Xie Master kapangidwe kameneka ndi kamangidwe ka nkhungu ka chivundikiro cha bokosi la nkhomaliro, kudzera pakuwunika kwa chivundikiro cha bokosi la nkhomaliro, kapangidwe ka pulasitiki ndi ukadaulo, ndiyeno zomveka, kukwaniritsidwa kwasayansi kwa nkhungu ya jekeseni. kupanga.

Freshness Keeper Ubwino wa kapangidwe kake ndikuchepetsa njira yopangira jekeseni momwe mungathere kuti zitsimikizire mtundu wa zigawo zapulasitiki, kufupikitsa kuzungulira ndikuwumba, kutsitsa mtengo wopangira.Mfundo zofunika pamapangidwewo ndi njira yopangira jakisoni, kamangidwe kameneka, kusankha kwapang'onopang'ono, kachitidwe ka gating, kachitidwe ka ejection, makina oboola, makina oziziritsa, kusankha makina opangira jakisoni ndi cheke cha magawo ofunikira komanso kapangidwe ka magawo akulu.

Mapangidwe apadera a Freshness Keeper ali pakupanga makina otsanulira, kuthira manja a chipata ndi kuika mphete pa gawo limodzi, kuonetsetsa moyo wa nkhungu, ndi kusankha zinthu, kukonza, kutentha kutentha ndi kusinthanitsa ndizosavuta;Chipata ndi mtundu wa chipata cholunjika, chomwe chimafuna magawo awiri olekanitsa, ndipo mtunda wokhazikika wa drawplate umagwiritsidwa ntchito kuchepetsa kugawanika koyamba.Mapangidwe ake ndi osavuta komanso omveka.

Nthawi yotumiza: Nov-01-2022